DIY Page - Ortobi82

75% ortholinear keyboard

2023 EDIT

Full disclosure, those were my first tries into keyboard designing and making - none of the original text i wrote about is modified. i use colors to add further comments and additions.

Board Design & Developpement

Old Versions (1, 3)

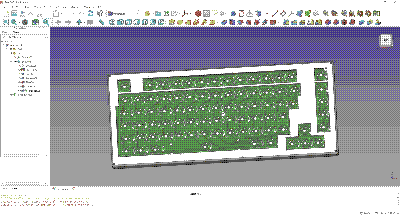

I use KiCad. which i tried and tried until i found out i had to use some nighly build because pre-6.0 versions are just the worst to use (the 6.0 wasn't out yet)

First version used Elite C microcontroller a Pro Micro clone. I lost my shit when i had to build a firmware with QMK tools.

The transistion between pre-6.0 and 6.x was painful, a huge majority of tutorials were made in almost prehistoric times,completly irrelevent. I also created a full folder of parts once i got familiar with the nightly build, after that i continued to use this build even after final 6.x release.

I had some pcb routing errors, i scrapped all the QMK stuff and went for something easier and appealing in Micropython/Circuitpython. And I learned I cannot do matrixes over a MUX and direct inputs from the board -despite all the documentation I read. i need to read docs better. The last PCB i did was ok-ish.

I've had help for routing from a engineer not specialized in pcb manufacturing but that knew more about it than me, and he showed me some stuff, and from that fresh knowledge i did some mistakes.

For firmware choices i had a hard time understand how i'm supposed to use QMK and it was at the time the point when i saw the project called KMK the CircuitPython varient of QMK, which its based on C.

Current Version (6)

That one is actually perfect, no routing errors, no more uses of multiplexers, more barebone. An it can goes with a lot of boards such as Arduino's Pro Mini, Sparkfun's Pro Micro. Elite C board. Any controllers with the same form factor and pinouts as Pro Micro can go.

Intended to use this version with AdaFruit's KB2040|RP2040 "KeeBoar" for testing purposes. It supports Micro/Circuitpython, and i saw it can be flashed with Arduino code too.

Enclosure Design

Early versions used cardboard the same folds as a shoebox.

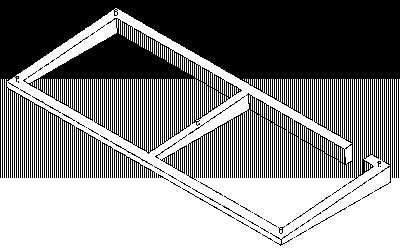

I've dabbled FreeCAD for this kind of work. i didn't designed many enclosure cases design. it's my first time. I don't have a 3D printer so a friend is actually give me some help there. It use additionnal parts, 5 M3 female threaded knurled nuts with 5 round and cruciform (Philips) M3 screws.

The bill of material was nice and easy, but for cheaper build i also designed nails and holes in the board that can fit really well.

Little revisions

Due to the size of my friend's 3D printer i have to cut every piece in two

Update Oct 23:

Case got a redesign. All the bottom print is now a kit. Based on that.

Assembly

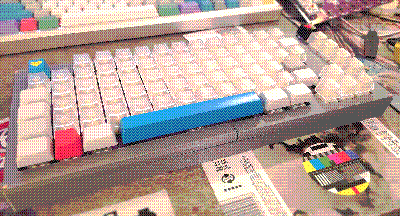

Prototype is finished

3D printed in 4 parts with a newly built Prusa MK3S+ Printer. All parts needed revisions after the print.

This was the most enlighting build i ever did. the first one but i also manage to get it together over time. I still find some little modification to do, other layers to test and it's a great build for doing so.

Return to Keyboard index page

Return to DIY index page